DI supported the Technology Application Laboratory of a Multi-Energy Services Group in Japan

• Client: The Technology application laboratory of a Multi-energy Services Group

• Country: Japan

• Industry: Manufacturing

Background:

The Japanese manufacturing industry is currently grappling with several challenges, such as manpower shortages and risks associated with supply chains. To address these issues, the concept of a digital twin has emerged as a potential solution. However, the high cost of implementing such a system poses a hurdle for small and medium-sized enterprises (SMEs).

Support Overview:

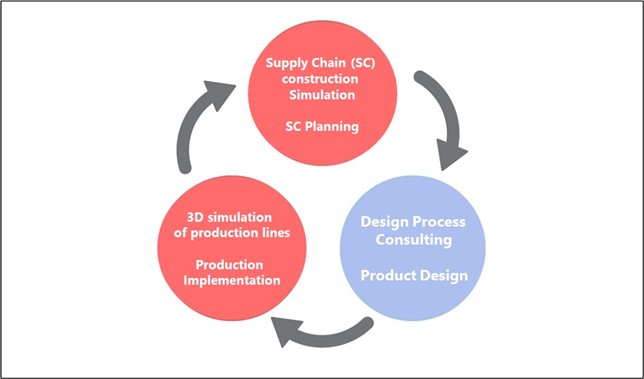

DI and its partner have joined forces to develop a platform that utilizes digital twin technologies to optimize the production process for SMEs. The three services offered by this platform are “3D simulation of production lines,” “design process consulting,” and “supply chain construction simulation.” To increase efficiency, a manufacturing facility is simulated in 3D in “3D simulation of production lines” utilizing digital twin technology. Front-loading is made possible by “design process consulting” that does highly accurate simulations early in the design process. Companies using the platform are digitally linked to one another through the “supply chain construction simulation” to promote business opportunities and achieve overall optimization.

L7-11, 7th Floor, Vincom Center, 72 Le Thanh Ton Street, District 1, HCMC, Vietnam

info.vn@dreamincubator.com.vn

+84 28 3827 8450